Everybody, everybody uses drywall in their builds. We don’t have it anywhere near any of our build sites and we have 12 projects going on right now. And one of the arguments against drywall or for drywall if you will is cost obviously. A 4′ x 8′ sheet costs about $10 in most environments.

So we don’t use it. We use strictly veneered plywood and we’re going to tell you why and we’re going to kind of dispute some of the reasons that people use drywall. I think veneered plywood, most markets $60-80 a sheet so there’s a big cost difference. But let’s look at plywood’s advantages versus the cost and we’ll see what we can come up with.

A lot of the arguments for drywall is “Oh, it’s a good sound absorbing material and it’s much better than plywood.” Well, that’s not true, okay? This is a myth that people have bought into over the years and they haven’t checked the data. Let’s look at the data.

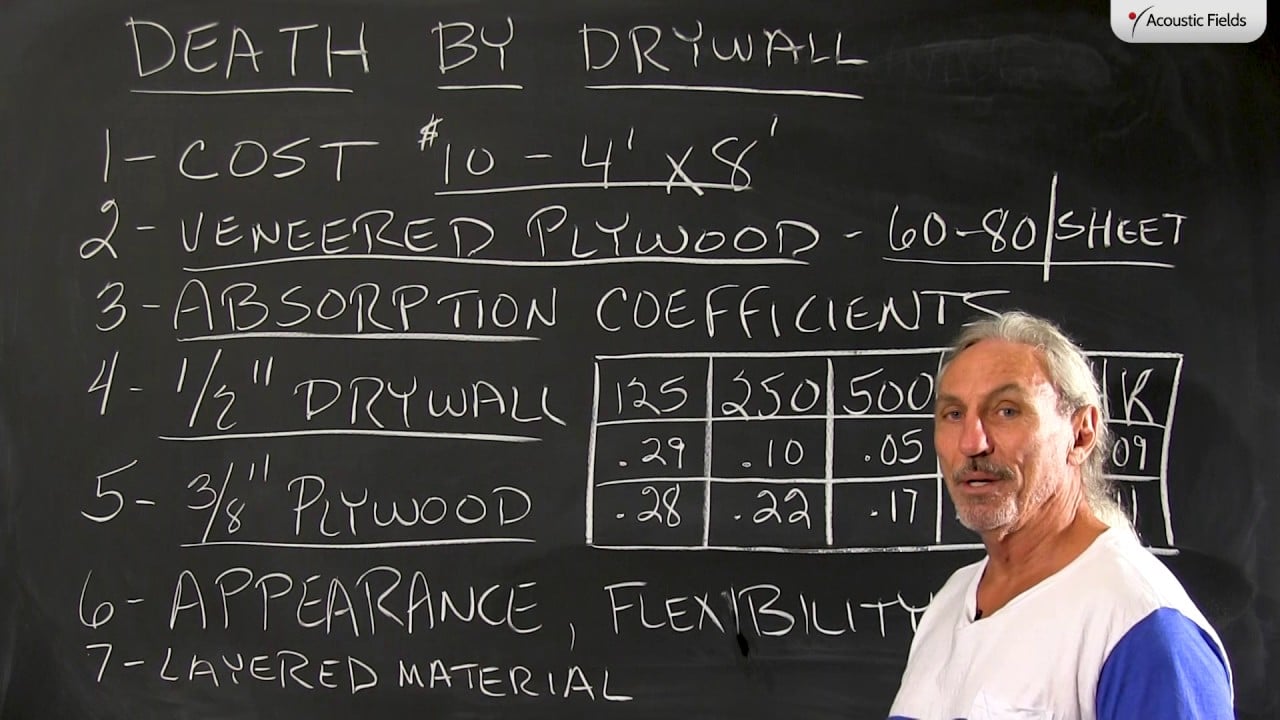

Just a half inch piece of drywall we all know what absorption coefficients are. You can look at the rate, you can look at the frequency 125, 250, 500, 1K, 2K, 4K and you can compare the absorption coefficients. 125, almost the same. 250, plywood is actually a little bit stronger in the absorption. 500, pretty close. 1K, 2K and 4K, there’s hardly any difference. So the argument that drywall is a better sound absorption material from 125 to 4K, simply not true. Okay?

That’s another myth people bought into overtime. Don’t assume that because everybody is doing it, that it’s correct. The reasons behind the fact that they’re doing it may not be good reasons at all. They may be doing it because that’s what they’ve read, that’s what they’ve heard, that’s what they’ve seen. Resist. Obey a little and resist much. I mean those are the models when it comes to acoustics. Don’t do what everybody else does. If you look at your old studios that were built in the 50’s and 60’s wood was dominant everywhere. Okay? So were 14-foot ceiling heights which we’ve lost.

So appearance with veneered plywood is off the scale much better than drywall. So you have the flexibility with the appearance you can match and coordinate and contrast with the course and it’s a natural material. We always want to stay with natural materials when we’re dealing with sound and audio in our rooms.

Here’s another big advantage between plywood and drywall. It’s a layered material so there’s some vibrational energy management tools built right into the product. Most plywoods we use have 10, 12, 14 layers to them. So we know from our examples that we want the room to move less. But if we want the room to move less we build the room with materials that take out that kind of energy that causes the room to move.

So a series of layers with plywood we get an energy sink built into the product. We don’t get that with drywall. And the absorption coefficients are about the same. This is going to be the first in a series of where I go after drywall and I’m going to try to change your thinking on it. Don’t just assume that you’re going to use drywall.

Now, if the cost is a factor, change your thinking on it. Don’t just assume that you’re going to use drywall. Now, if the cost is a factor and you don’t have budget because it’s 6, 7, 8-times more money but think about it. You’re just going to skin the whole room in drywall or you’re going to skin the whole room in veneered plywood. Maybe the cost difference is a 1000 to 1500, to 2000.

And ask yourself, would you rather work in a room that’s surrounded by natural wood or crushed rock? Okay? That is your real bottom choice. And we’re going to do other videos on the sound quality of it, okay? So we’ll talk about that later but right now I just wanted to address the thing that I hear all the time “Well, we have to use drywall because it has better sound absorption characteristics than plywood.” And you can see from this data that it’s not true.

—

This is an unedited transcript from our video series from Acoustic Fields. There will be some errors in grammar and sentence structure that occur during this translation process.

For complete understanding and comprehension, please view the video which is included in this text. For any additional information regarding this topic or others relating to room acoustics, please contact us directly at:

P: 520 – 392 – 9486

Are you referring to average drywall? There are specific acoustic drywall products on the market that are significantly denser, use different materials and (claim to) offer far more acoustic benefits over the cheap stuff you’d find in any DIY store. Or are you taking that in to account with your figures when comparing? I’m aware these specialist drywall products are considerably more expensive, but still cheaper than veneered plywood.

With the veneered plywood, do you just use a single layer? Much of the advice I’ve read regards drywall installation for acoustic purposes (which you may or may not agree with) seems to focus on have x2 layers, often with Green Glue or Tecsound in between. What’s your approach? If I was decoupling from brickwork with a stud wall, would I just put a single layer of veneered plywood on that (with some insulation between the studs)? Or would there be another layer(s) of something behind it? Thanks.

J, All materials have a “sonic signature”. Wood “sounds” different than glass. There are frequency response aberrations that can prove this difference. The task then becomes what material to use to minimize any distortions created by the material. Our material approaches differ based upon sonic usage, pressure levels, size, and volume.

OK, that’s great to know, and all very interesting stuff… but I’m struggling to see how this is of much actual help to people. I don’t doubt what you’re saying, and history alone tells us that wood is a fantastic material for use in these environments… but there’s nothing really actionable in the info you provide, it’s not going to stop people using drywall.

You’re essentially saying here’s a better material to use, but I can’t tell you how to use it. I understand why, because every situation is different and it’s very specialised for the reasons you outline… sonic usage, size etc. That makes total sense.

So yes, if someone was employing you to build their studio/home theater then great, they’d be in the hands of an expert who knew how to wield the power of veneered plywood (and other materials) and maximise its potential… but otherwise, they’re just going to buy drywall, or an acoustic variant of it, because it’s FAR cheaper and the application/installation of it follows easier to follow guidelines… even if those guidelines result in a less than optimal result.

Again, I know you’re right… I wish I had your expertise and knowledge, but the only takeaway here is that unless I hire you to build my studio/home theater, I’m going to end up with a sub-par result no matter what I do, so either give up before I waste my money (and let’s face it, most people won’t do that)… or just follow the numerous guides that are out there regards drywall, insulation, Green Glue, Tecsound etc. because there really isn’t another option… short of hiring you.

It’s frustrating, but it is what it is.

J, Forty years of experience, expense, and knowledge do not come without a cost. Getting good quality sound is the result of doing a lot of little things correctly and just as importantly, in the correct order.

Yes, I fully appreciate that. I’m wondering though, for someone who is building their own space, would you not advocate veneered plywood over drywall? If they are happy to the pay the extra, is it going to net a better result in the majority of cases (it would certainly look nicer), or would a specialist acoustic drywall product sometimes be preferable?

J, It depends on usage. A large volume live room may work with drywall. Microphones “hear” differently than our ears. Treatment is critical. For critical listening environments such as control/mix, we use only furniture grade veneer. Yes, it does look better, especially the A – grade. However, its multiple layers actually reduce vibrations and we know that reducing vibrations, reduces noise.

Could it be used on top of drywall? For example, a layer of acoustic drywall with veneered plywood as a second layer on top? Or is that crazy? How do you fix it to the wall? Would you use cleats of some sort?

J, layering materials on wall surfaces is a good tactic. Gluing each layer together is best.

This is super helpful. I did 2 quiet rock layers between the house and my wife’s office, and another 2 quiet rock layers between her office and my office (along with angled decorative brick). It is so quiet. No kid noises to interrupt my work.

This methodology works for voice but not bass. There are much more effective ways to deal with lower frequency noise.