Table of Contents

Introduction

There is no such thing as a wall soundproofing panel. There is no such thing as “soundproofing”. With sound (noise) nothing is “proofed”. Noise and its associated process of transmission is mitigated or managed. When you are dealing with noise transmission, there is always some frequency length if the amplitude or strength of the signal hits a certain level. There is no wall sound proofing panel that will stop noise transmission. In order to stop or mitigate the frequency and amplitudes of your noise issues, you will need to build a barrier between the noise source and the receiver.

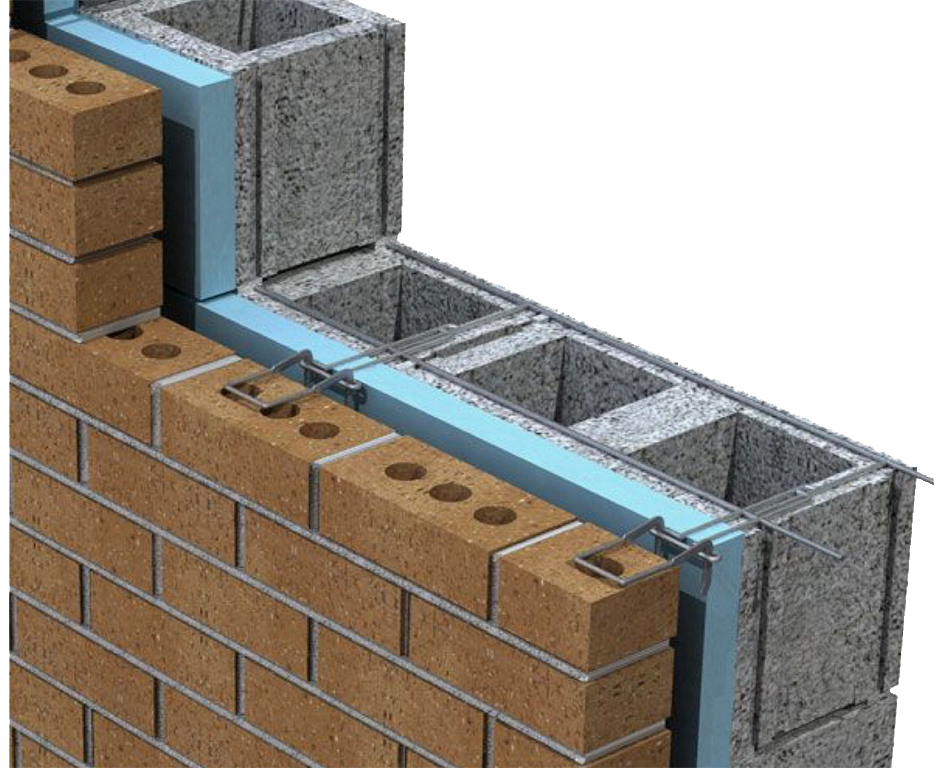

Barrier construction is a permanent construction fix. Building a quiet room is like building a boat that you will place in the ocean. It must be strong enough to withstand the waves of energy that wash over it. It must also not leak. Neither of these objectives can be managed with wall soundproofing panels. Sound is also like water. It will find the weakest link in the structure and go through it. A wall sound proofing panel is not a sealed unit. The sound will go around it and at some frequencies through it completely. Hanging something on your wall will not stop the noise from coming through the wall.

Rethinking Wall Soundproofing Panels

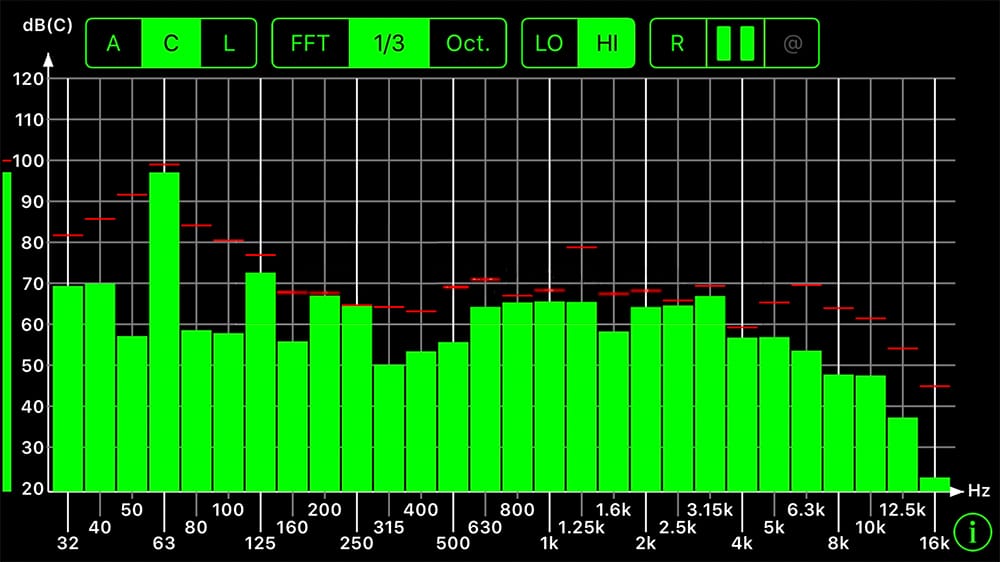

The term wall sound proofing panels can not be accurate for many reasons. Let’s look at what noise actually is and how we mitigate its transmission through our room walls. Noise begins as air borne energy that is generated from a source. That airborne energy has individual frequencies along with their associated strengths or amplitudes. This frequency amplitude distance must be kept in mind. As the noise is generated, it transmits through the air. This airborne noise then strikes our room wall surfaces. When it strikes our room boundary surfaces, it then becomes vibrations.

These vibrations then transmit through the material that the wall is constructed of. Certain wall material types along with their construction methodology will minimize vibration transmission at certain frequencies. Some designs are good at minimizing lower frequency vibrations. Some barrier types will work only on middle and higher frequencies. With noise, our goal is now to reduce the vibrational signature.

Building Barriers to Mitigate Noise Transmission

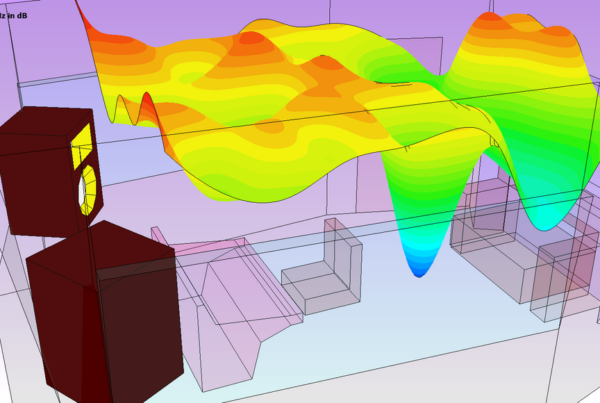

When we are dealing with noise transmission, we are really discussing vibrational acoustics. Vibrations just like airborne energy have a frequency response. It can be measured. The goal of any barrier design would be to minimize vibrational transfer from the air to surface contact. You can think of the frequency response of airborne energy as a snake. The same frequency response signature is represented in vibrational acoustics. Let’s call this vibrational signature a work.

The animal comparison is used to show the size difference in frequency response between the airborne energy and the vibrational signature. To mitigate noise or vibrational transfer, we must build a barrier between the source of the noise and us as the receiver. This barrier design and construction methodology must be based upon the frequency and amplitude of the noise we are trying to reduce the vibrational signature of.

Engineering Effective Barrier Designs

Any barrier design that is properly engineered will need to begin with noise numbers. Noise numbers are the measurement of the noise. Noise numbers quantify and qualify the noise. The noise measurements tell us the frequency of the noise issue along with the strength or amplitude of those frequencies.

All noise is not created equal. Lower frequency noise will usually have a greater strength to it. Every frequency has a material type that works well for that octave band or individual frequency range.

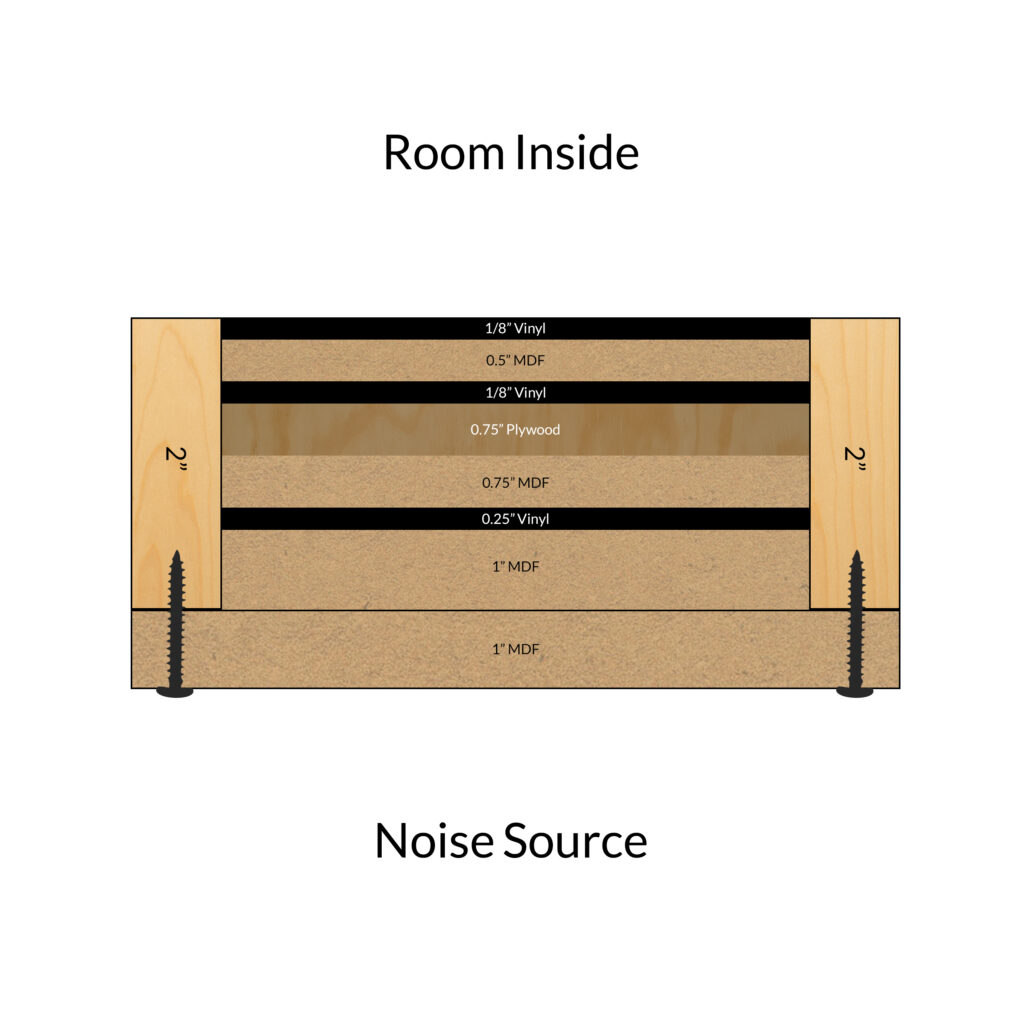

Knowing what material type to use to minimize the vibration transfer through the barrier at that chosen frequency is critical. Only an engineer with extensive building and testing procedures can meet the barrier design requirements for all noise types. Every material type used within a barrier design, the arrangement of construction methodology of that materials type is frequency and amplitude dependent. Once you know the frequency and amplitude of the noise, you can select the proper materials and construction methodologies to mitigate them.

Addressing Lower and Higher Frequency Noise Issues

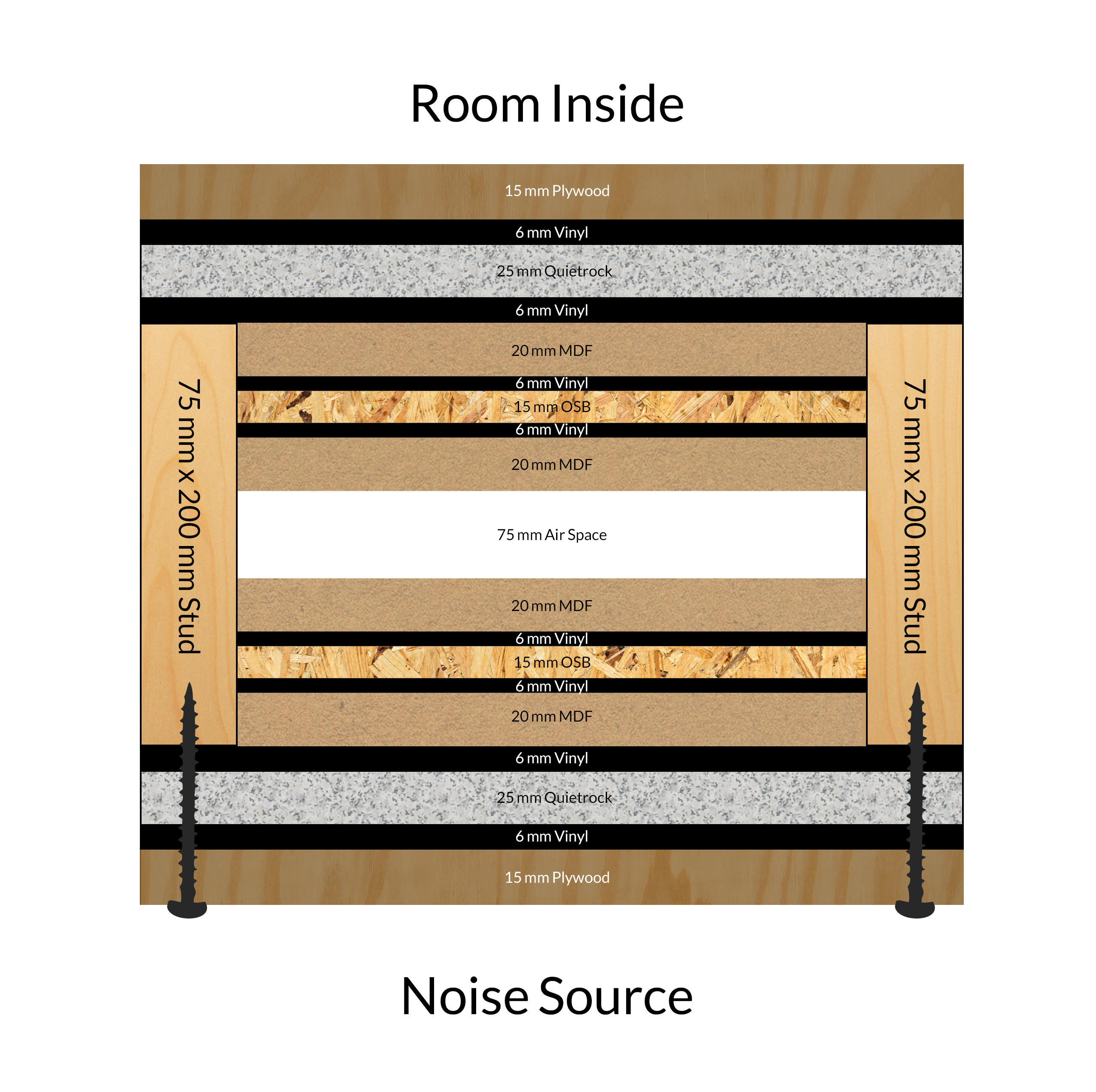

For barrier designs, we divide the measured noise into two main categories that vibrational acoustics requires. We have material types and associated barrier designs for frequencies below 125 hz. and we have materials and barrier designs for noise issues above 125 hz. The barrier designs for noise frequencies below 125 hz. will have more layers of certain material types. Multiple layers will add more mass or density to the reduction of lower frequency noise transmission issues.

Middle and higher frequency energy above 125 hz. will require material types that have less density. However, with middle and higher frequency vibration reductions, we must be careful on how these lesser dense material types are arranged in the barrier “sandwich”. All noise issues must be measured first and foremost. Guessing with noise is a fool’s game. In most cases, when you guess wrong, you will have to demo it and begin all over again.