We get a lot of emails and phone calls from people who kind of flip the treatment and the barrier technologies. They think that treatment which is the materials and diffusion and absorption that we use inside the room, they confuse that with sound isolation and noise transmission reduction.

So let’s kind of walk through the principles in our barrier which is our shell of our studio and not worry too much about absorption and diffusion in this process. So this is about creating a gate, a valve if you will, against noise. Keeping noise out and keeping the noise that we generate inside the room in. So it’s a valve that kind of controls that.

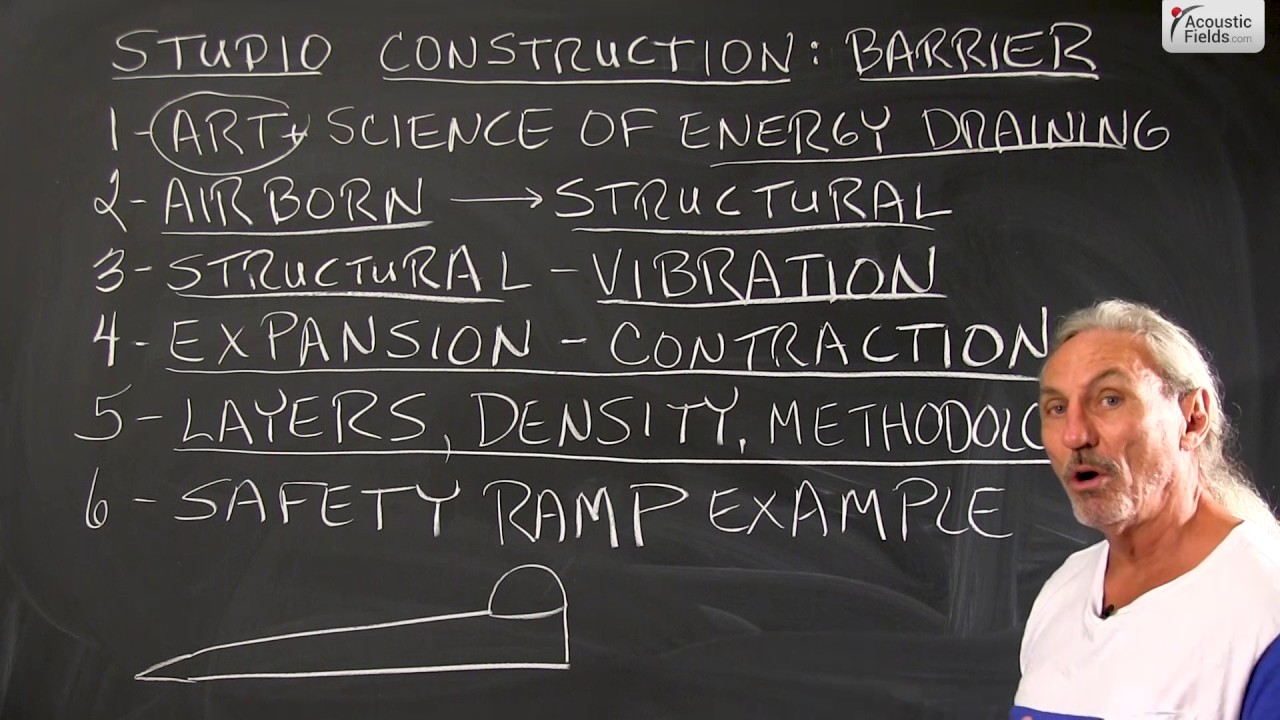

So barrier construction is really the art and science of energy draining. We’re trying to take the energy that strikes the surface of our studio whether it’s a garbage truck, whether it’s a neighbor yelling and screaming, whatever the noise source is. We want to make sure that we cannot have it get through our barrier into our room, okay? So it’s an art and science and we’ll talk about why that is.

So what do we have? We have our propagation or our path of sound is through the air. So the garbage truck goes by, our sound goes through the air and then it strikes a structure. When it strikes a structure the whole thing changes and the science changes in the vibration. So now we’re looking at reducing vibration, thus the term energy draining in the barrier technology itself. Now, how do we do that?

The goal in any structure when you’re designing a structure that’s all about sound. And really, any structure that’s dealing with isolation. When the energy strikes it it’s going to change shape. Now, you’re not seeing it but it will change shape. So it changes shape. And the goal of a good engineer and a good designer is to make sure that the shape change because it’s going to change, especially with low frequency energy.

The structure gets back to what we call homeostasis or balance as fast as it can. We don’t want it doing this. We don’t want it moving. If a garbage truck goes by, it moves a little but gets back to its original form quickly. And that’s in the design process. And here’s where the art comes in, okay? Because there’s all kinds of ways to achieve this energy reduction. And this is where the experience of the design engineer comes into place.

I looked at some drawings the other day of a cyclist gym in California where they have two subwoofers and they’re right next to office buildings. And they sent me the drawings and the drawings had no barrier technology at all. And how are they going to stop these two 15 inch drivers and 55 cyclists from radiating this energy through this wall which was a 2 x 6 wall with building insulation and just drywall. How are they going to keep that from the neighbors who were working at their desks in the offices next door? And they’re not.

So how do we do it? Experience. Methods, tried, tested, failed, succeed, all kinds of. I’ve been doing this for 40 years. I have tried all kinds of methods for isolation. So the secret I have found, it’s in the layering, it’s in the density of the materials you use and it’s also in the way you put those materials together. So there’s 3 variables that you have to consider.

Let’s go back to the philosophy first about what we’re doing. We all know, or we’ve been driving on roads where the trucks go down steep hills through mountains and they have these safety ramps for the trucks to pull off of. What is the purpose behind those safety ramps? The whole purpose behind the safety ramps is energy-draining. We’re trying to take the forward momentum of the truck. We’re going to use gravity because the ramps usually are at 45 degree angles. So as the truck goes up the ramp it dissipates energy. Now, it’s got no brakes, right? Because it’s on the safety ramp because its brakes failed.

So what are we doing? We’re elevating it, slowly and steadily and as the truck goes up the ramp we’re draining energy. That’s what we’re doing. We’re using gravity to drain energy, alright? Now, if we don’t do our job and the truck is going a little bit too fast, what do we have at the top? We have a pile of sand for the truck to hit. Or water. Some kind of medium. That will stop it, okay? But the goal is to try to get the energy to drain off the forward momentum of the truck.

The same thing we’re trying to do with energy in the air when it strikes a structure. We’re going to have a series of layers, very similar to this. And as the energy strikes, those big, little, get through the air and then when it comes out here it’s smaller. Reduced in amplitude, reduced in strength. Not in frequency but reduced in amplitude and strength. So that’s our goal. Series of layers, different materials, different densities arranged. It’s little bit of an art and science and we’re taking airborne energy running it through a structure and reducing it.

I hope that helps. Don’t confuse it with absorption and diffusion, completely different science. There is some overlap but the key to the understanding of barrier technology is understanding the differences and the likenesses between the two sciences.

—

This is an unedited transcript from our video series from Acoustic Fields. There will be some errors in grammar and sentence structure that occur during this translation process.

For complete understanding and comprehension, please view the video which is included in this text. For any additional information regarding this topic or others relating to room acoustics, please contact us directly at:

P: 520 – 392 – 9486