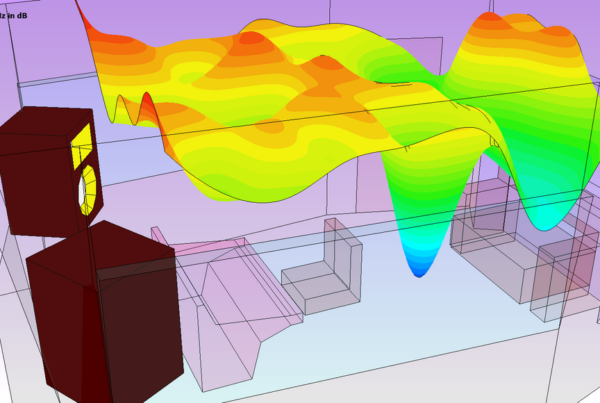

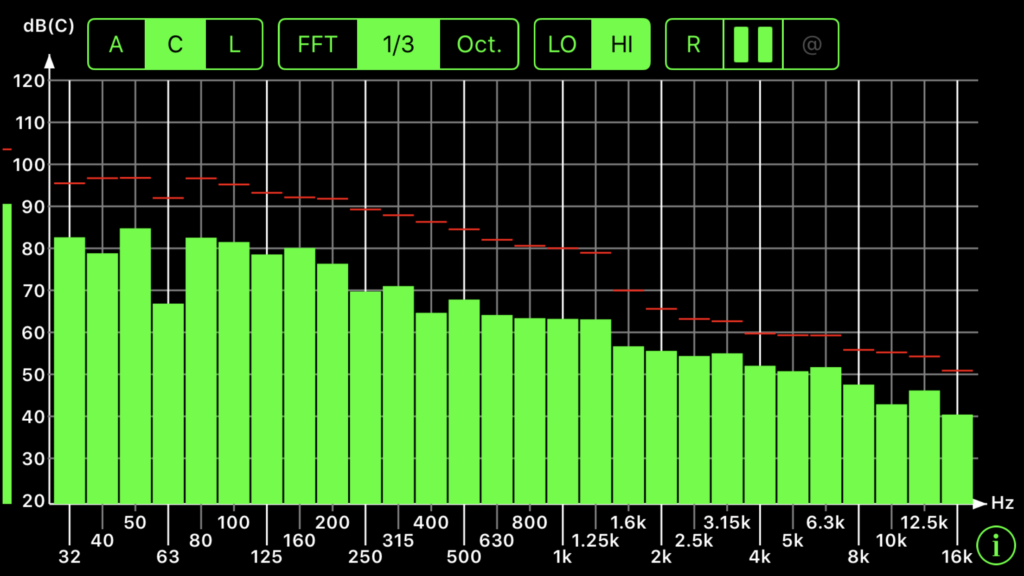

The term soundproofing is a misnomer. With noise transmission, nothing is “proofed”. If your goal is the soundproofing of existing walls, then you must be realistic in your expectations and realize that noise is managed. The goal is to reduce the noise levels below the noise floor that already exists within the room. Let’s define some terms so we can assist you with soundproofing existing walls. Our first objective with any noise issue is quantifying and qualifying the noise issues we are facing. What are the frequency and amplitudes of the noise that we are trying to mitigate. To mitigate noise, we build a barrier between us the receiver and the noise source, say a garbage truck. The barrier design will focus on the frequency and amplitude of your specific noise issues. We must measure the noise over a seven day time period so we can achieve a pressure map of what is going on within your room and what noise frequency and amplitudes exist outside your room. Every noise situation is different and specific to the existing room construction and usage along with the ambient noise levels within the neighbourhood.

To measure noise, at Acoustic Fields, we have a measurement process where you can take the noise measurements yourself with your cell phone and use the internal microphone. https://www.acousticfields.com/sound-barrier-technology/ We send you the apps and you download them on your phone. You follow our noise measuring process by watching our instructional video. You take the measurements over a seven day period measuring the quietest part of each day and the loudest part of each day. This measuring process produces minimum and maximum pressure readings for each day. The reason we measure noise over the seven day time period is so that you can have a room that you can work or live in any time of the day or week. Once you have taken your noise numbers, you then record those numbers on our online data sheet and then send it to us. We will analyze the readings you took and then design the proper barrier technology that you can build yourself or have a contractor build for you. All of our barrier designs use standard construction materials and methodologies. https://www.acousticfields.com/noise-time-study/

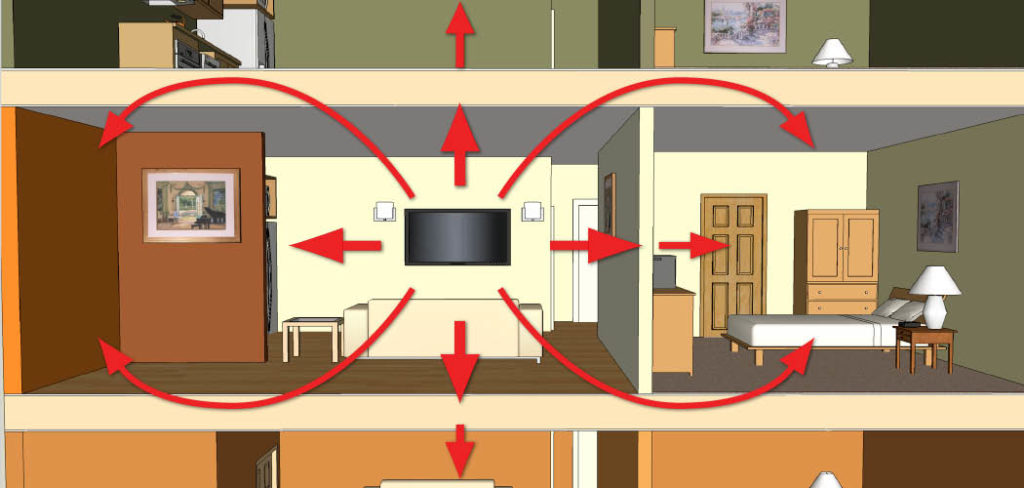

Soundproofing existing walls is only part of the noise equation. We must also focus on the floor and ceiling. Noise is like water. It will find the weakest link and go through that space. Noise will also flow around walls and can enter your room at any weak point. Windows are a common weak spot in any wall design. When sound or noise flows around existing walls, it is termed flanking noise. https://en.wikipedia.org/wiki/Acoustic_transmission. Treating the walls, floor, and ceiling are essential if we are going to keep our “boat” floating on top of the water surface. Our rooms are like boats when it comes to noise. We can not have any holes or leaks within the structure to allow water or noise to enter. Our boat must have all leaks filled with the proper material type and amount so that the noise numbers you have taken are dealt with accordingly. Not all noise frequencies and (amplitudes) are created equal. Lower frequency noise requires a much different barrier to build than middle and high frequency noise transmission.

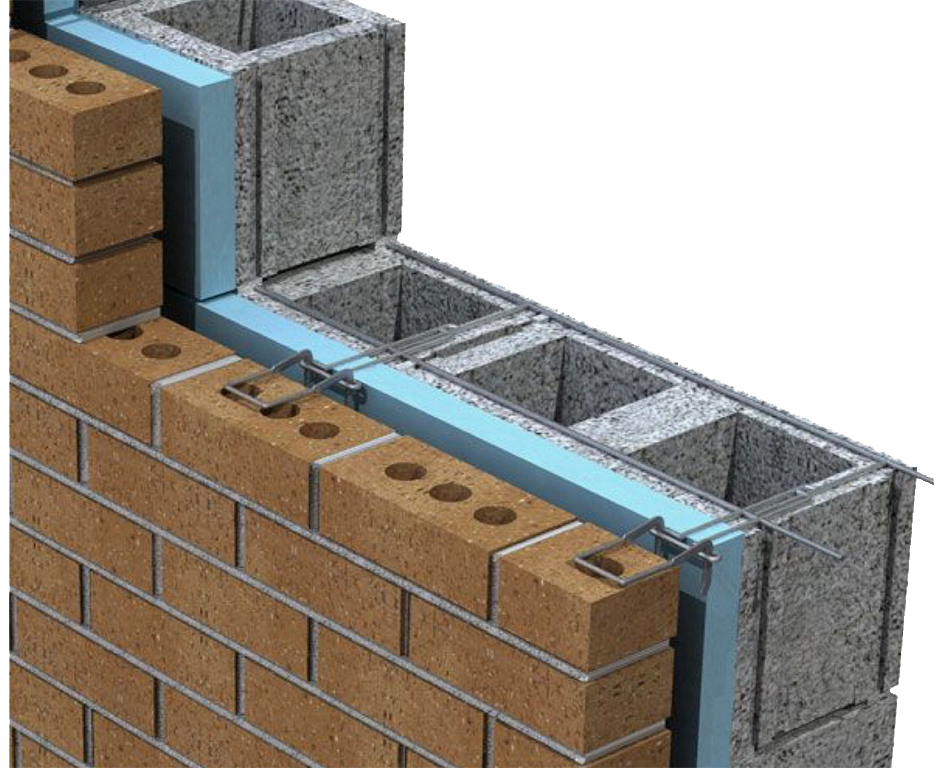

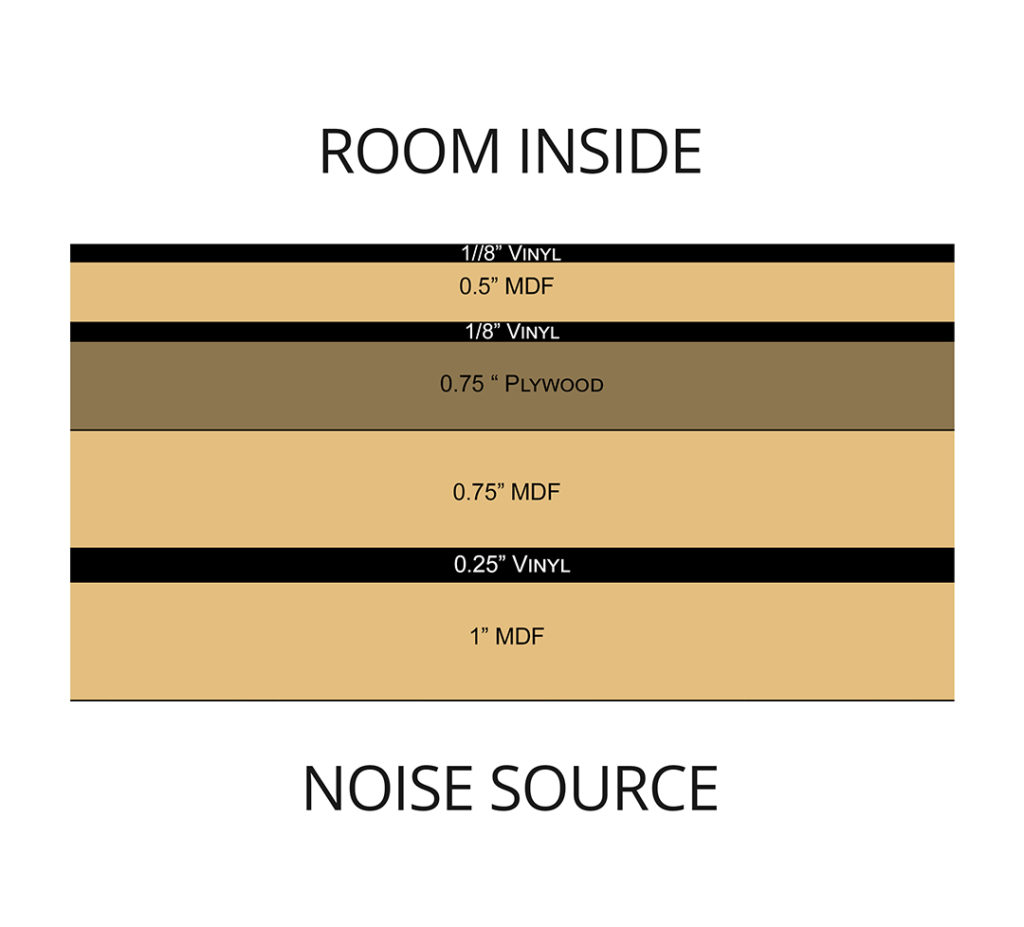

Lower frequency noise energy is energy that falls below 100 Hz. If you have noise https://www.dictionary.com/browse/noise in this frequency range, you must pay special attention to the design and build of your barrier. Low-frequency noise such as a garbage truck not only sets off alarms in the parked cars but will penetrate almost all structures no matter what the material type used to build it. Low-frequency barrier technology has mass or density and it is constructed in such a manner to reduce vibration transmission. Noise travels through the air and strikes a wall surface area. When the airborne noise strikes the wall, it then becomes vibrational energy that will transmit through the exterior of the wall and travel into the room. With lower frequency noise transmission, we must use the proper material types and arrange them in the proper order to minimize the transfer of vibrations. If you have ever driven in the mountains, you will see exit ramps for trucks that have lost their brakes. The truck pulls off the road onto the ramp and then the ramp extends upward at a 45 degree angle so the forward momentum of the truck is slowed by gravity. Hopefully the truck runs out of forward motion before it reaches the water or sand bags at the end of the ramp.

We use this same process of bleeding energy when it comes to noise transmission. We must look at the vibration signature of the noise and then design the barrier to reduce the vibration transmission through our walls. With lower frequency issues, we use a denser material type facing the noise source. As the noise energy strikes the outer surface material type, it then travels through that material into the next layer in our barrier. As the noise vibration moves through each layer, we are bleeding off energy just like the truck ramp. By the time the noise energy travels through the barrier, its vibrational signature will be reduced and fall below the existing noise floor within your room. Having a low noise floor in your critical listening or working room increases resolution of both music and voice.