Acoustic foam is an economical way to absorb middle and high frequency absorption. It is not a low-frequency treatment type. It is for middle and high frequencies only. Acoustic foam is manufactured in molds and can be made to any thickness desired. The thicker the foam, the lower the frequencies it will absorb. Most acoustic treatment foams come in 1/2″, 1″, and 2″ thicknesses. Foams have different rates and levels of absorption. A lot of foams in the marketplace try and absorb as much energy per square foot as they can. This process we will term noise foams. There are other foams that will have a rate and level of absorption that was specifically designed for music and voice. All foams are not created equal. Most foams are designed for noise while a small percentage are designed for music and voice. Stay with the foams that are designed for music and voice. Where do we place foam and how to hang acoustic foam are common questions. Before we address those issues, let’s look at the packaging of acoustic foam.

Acoustic foams can come in just raw foam or it can be packaged in a box with fabric covering the foam. The box can be wood or some other material type. The fabric can have many colors and textures to match any decor. This fabric box construction methodology is the most expensive way to use foam technology. Another method that is available is to use just the raw foam. Some foam types are rigid enough that you can just attach the raw foam to any surface area. There are many methods available on how to hang acoustic foam. You can use a product called “Alien Tape” which can be attached and removed to foam and wall surfaces easily without leaving any holes or marks. The 3M corporation also makes many adhesive types that you can use and answer the question on how to hang acoustic foam. Whatever foam type you choose, you must first know what type to use and how much of it you require to complete your sonic goals.

Fabric Color and Textures: https://www.guilfordofmaine.com/acoustic

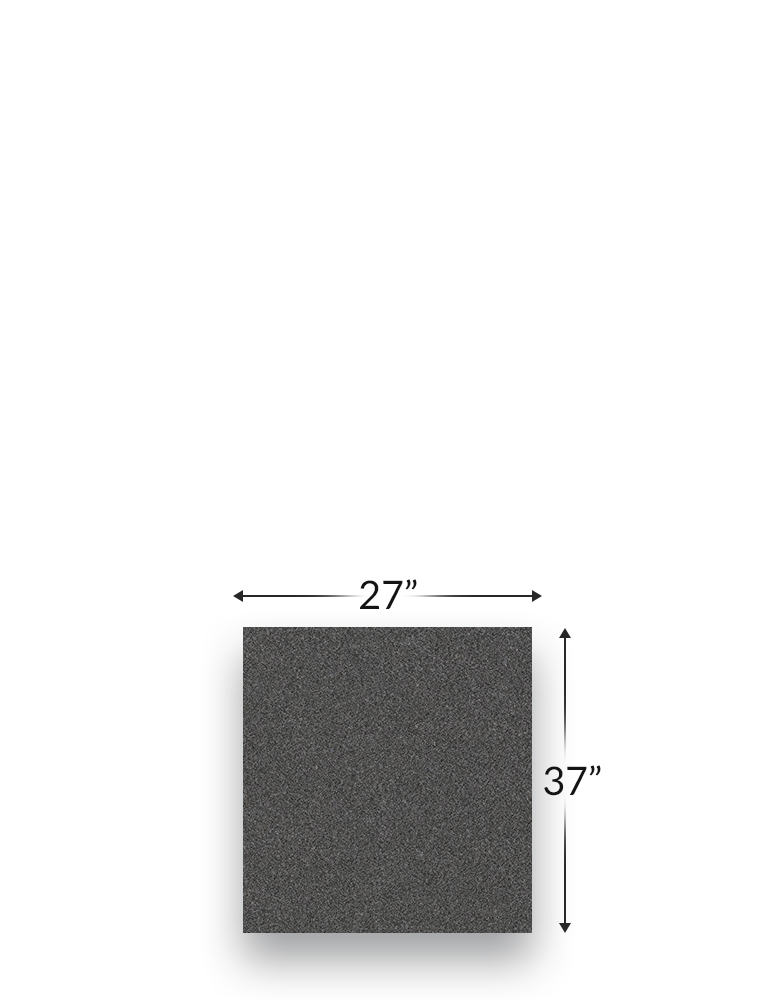

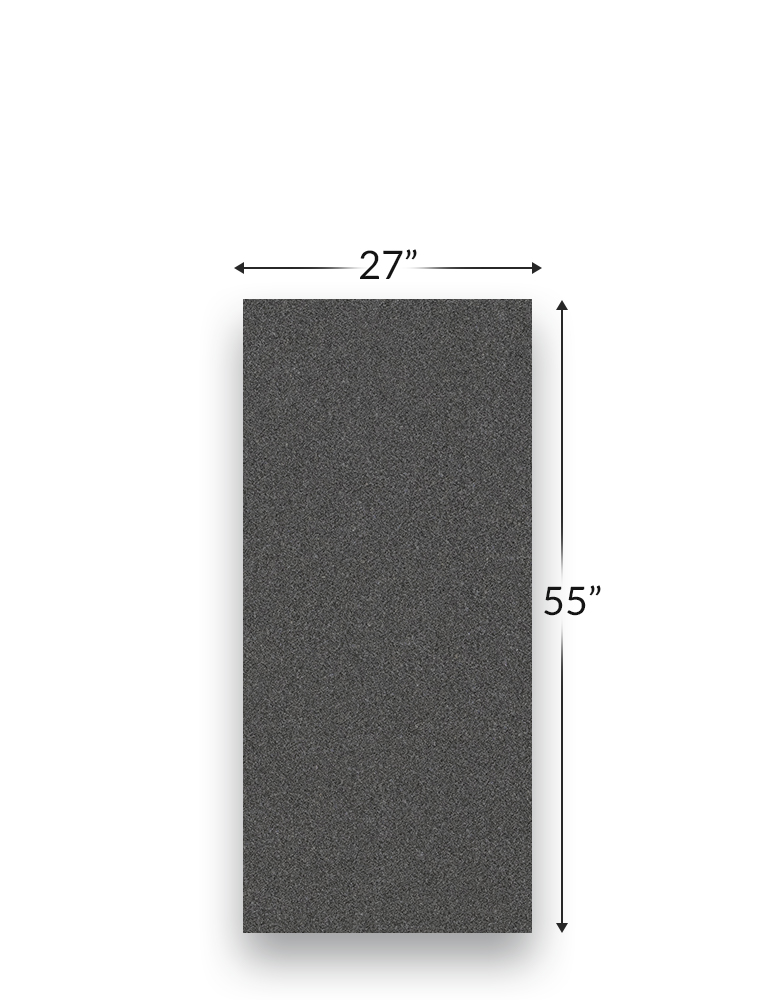

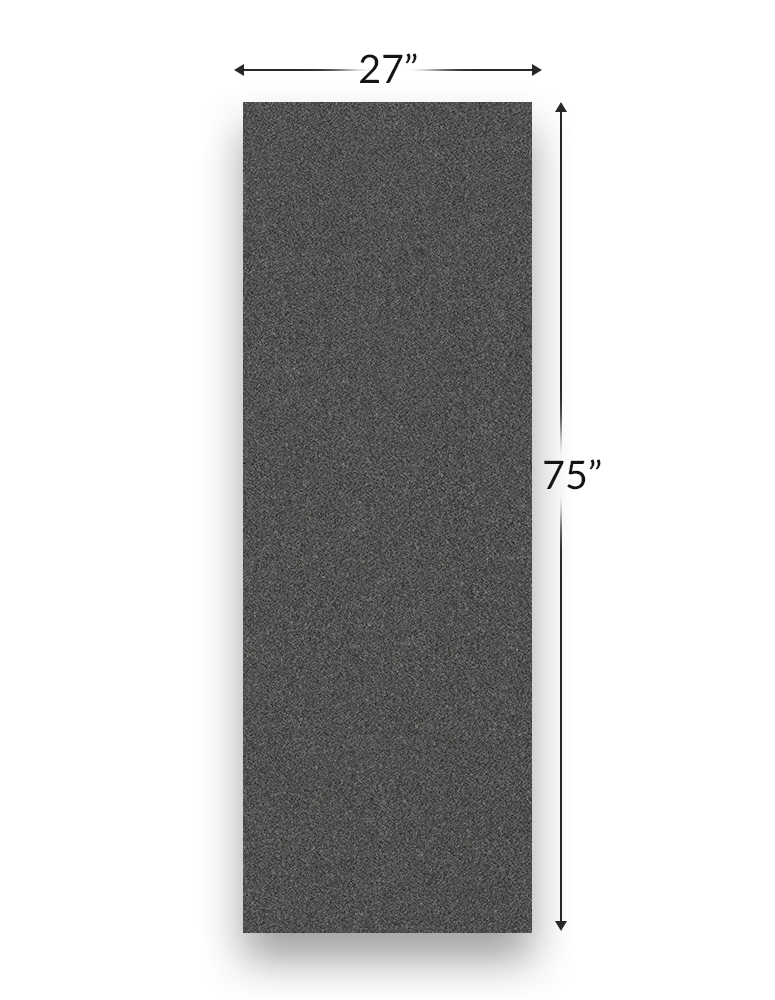

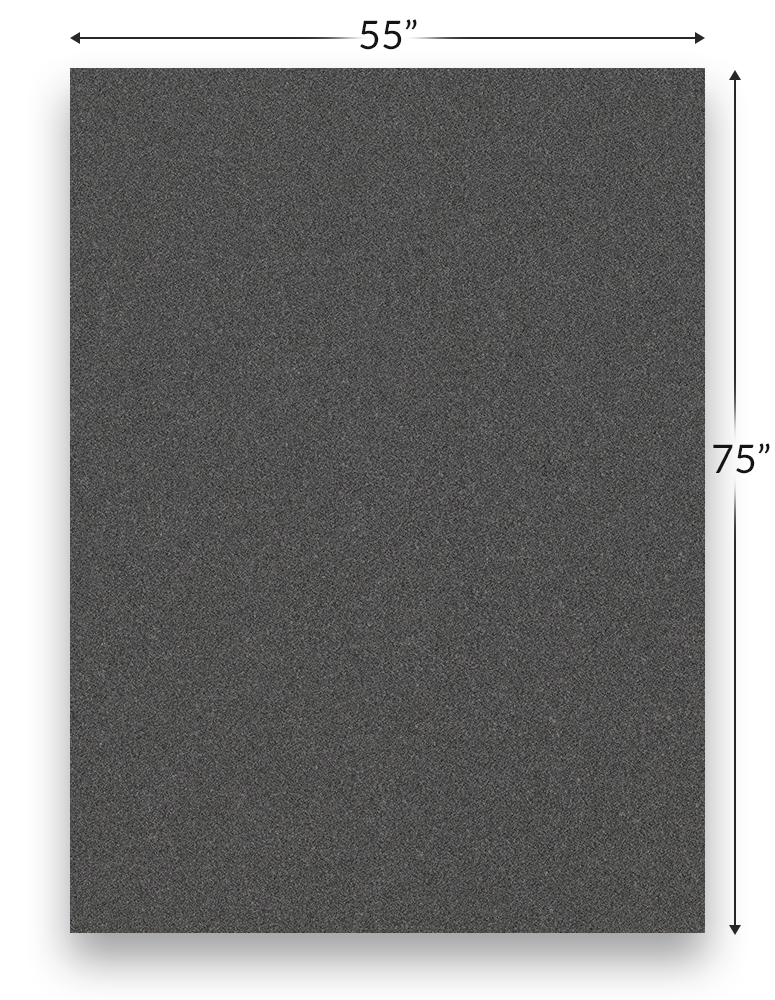

Our proprietary foam technology is not rigid enough to support itself using our larger pieces. We make foam in four main sizes. You can see in this link the sizes we offer. The small 18″ x 25″ x 2″ pieces can easily be used with the wall hanging methods we described above. For the larger pieces, we have built a wood frame around the edges of the foam to provide the rigidity required for how to hang acoustic foam. The wood frame provides the structural rigidity we need to hang the foam from the walls. The Foam Frame Panel can be hung vertically or horizontally to match the goals of the room. How to hang acoustic foam will depend entirely on the surface area you must treat and the usage of the room. What are we doing within the room? Are we mixing or recording live instruments? Every usage has different surface area requirements.

Foam Frame Panel: https://www.acousticfields.com/product/foam-frame-panel/

Acoustic Fields Foam Sizes: https://www.acousticfields.com/acoustic-foam-overview/

We make only foam technologies that are designed for music and voice only, not noise. Our proprietary foams took 8 years to develop at a cost of over 2 M. It is used all over the world and it has the smoothest rate and level of absorption that is required for music and voice. The rate of absorption for foam is defined as how much absorption is absorbed through the frequency range. The level of absorption is how low in frequency will the foam absorb down to. You always want to match the rate and level of absorption to your room requirements to your acoustic goals. With acoustic foam it is always about surface area coverage. You must cover enough surface areas with the correct amount of treatment type and amount. You must also match the surface area coverage with the usage of the room. Live rooms that you use to record instruments are different from the vocal rooms. Every room size and usage has different reverberation time acoustical requirements.

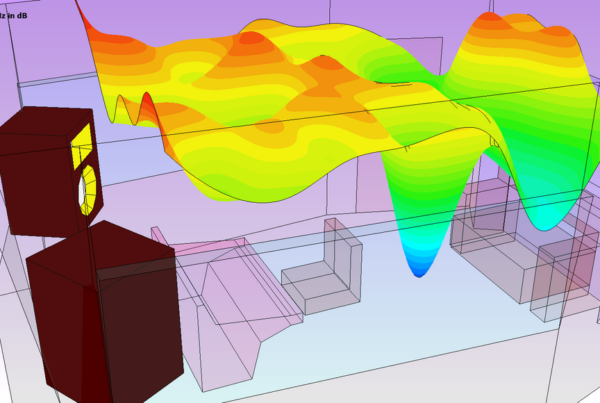

The major offender to small room acoustics is reverberation times. Reverberation is how long a sound stays around within the room after it has been created by an instrument or vocal. Reverberation is created by the reflections from all of the wall surface areas. Every room surface area contributes around 17% to excessive reverberation times. To lower or minimize the strength or amplitude of the frequencies that are reflecting off of the wall surfaces, we need to use foam panels to cover at least 70% of the surface area that is producing the problems. We will first need to know how to hang any acoustical treatment types across the offending wall and ceiling surface areas. Once we have that issue resolved we can then decide on how much surface area is to be covered to reduce the reverberation times down to manageable levels for our intended usage.

About Us At acoustic Fields: https://www.acousticfields.com/about/