You have two major choices to make regarding the management of sound energy within our home theater, personal listening, and professional control rooms. You can absorb or diffuse sound energy in order to manage it correctly. You can use absorption to manage low, middle, and high frequencies. You can use diffusion to manage middle and high frequencies. It is a blend and combination of these two technologies that go into each of our sound rooms and why DIY bass absorbers and diffusers could really make a difference for you. We have updated this blog on 12/5/19 to reflect current knowledge and experience.

DIY Bass Absorbers And Diffusors

Acoustic Products Expensive

Quality room acoustic products are expensive. You also need numerous units to treat the surfaces of any room. To have any sonic impact from room acoustic treatment, at least 25% of the surface area must be treated. In a control room, we have the rear wall which normally would be treated with diffusion. Both side walls must be splayed or angled to minimize side wall reflections. The surface area of each sidewall is treated with absorption. Low-frequency management is essential in any room whether a listening room, home theater room, or professional recording studio. With today’s smaller rooms, low-frequency control must include numerous units.

Foam: https://www.acousticfields.com/product/acoustic-foam/

Wood Shop

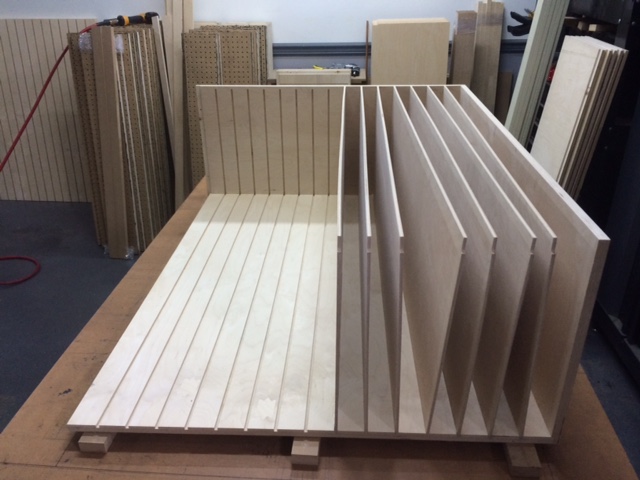

If you have access to a small woodshop with a saw, it can be table or handheld, and you have some woodworking skills, you can build your own professional DIY bass absorbers along with middle and high-frequency absorption and diffusion. There are no angles to cut, everything is a straight line. Build drawings are provided with assembly instructions and an actual step by step build with photos. A tool list, cut sheet, and material complete everything you need to build your own units.

DIY Bass Absorber Build Plans: https://www.acousticfields.com/product/diy-bass-absorber-build-plans-bda-broadband-diaphragmatic-absorber/

- Quadratic Diffuser Interior Vertical Wells

- Quadratic Diffuser

Low Frequency DIY Bass Absorbers

There are many types of sound absorption devices available that claim to be bass traps or low frequency absorbing devices. There is a standard box filled with building insulation. Foam wedges are another popular unit that is claimed to absorb low frequencies. None of these units are really low frequency absorbing devices. John Storyk, the principle of Walters Stork Design Group, did a test on all of these devices in 2006 and published his results in an AES paper. His conclusion was that of the eight units he tested, only one actually did work as claimed. It was a membrane absorber with the densest front panel or another term could be diaphragmatic absorber.

Diaphragmatic Absorber Construction

Diaphragmatic Absorber

A diaphragmatic absorber is a cabinet that has a front wall that moves or vibrates in sympathy with the amount of sound pressure that is exerted upon it. The cabinet is more rigid than the front wall and is designed this way on purpose. The depth of the cabinet and the density of the materials used are critical in determining the frequency of resonance of that cabinet. One can design a diaphragmatic absorber to absorb any low-frequency issues within a room. Foam wedges and boxes filled with building insulation can not.

Cabinet Fill Material

Inside the cabinet, there is an internal cabinet fill, usually some type of building insulation material. One can take the internal fill material and expand upon it to increase its efficiency. The internal cabinet fill material must absorb internal cabinet resonances and also contribute to the cabinet’s overall performance. It is by far the only low-frequency absorber that has the horsepower to actually tackle the energy generated from low-frequency wavelengths. Diaphragmatic absorption is used extensively by the top room designers when they are designing and building multi-million dollar rooms.

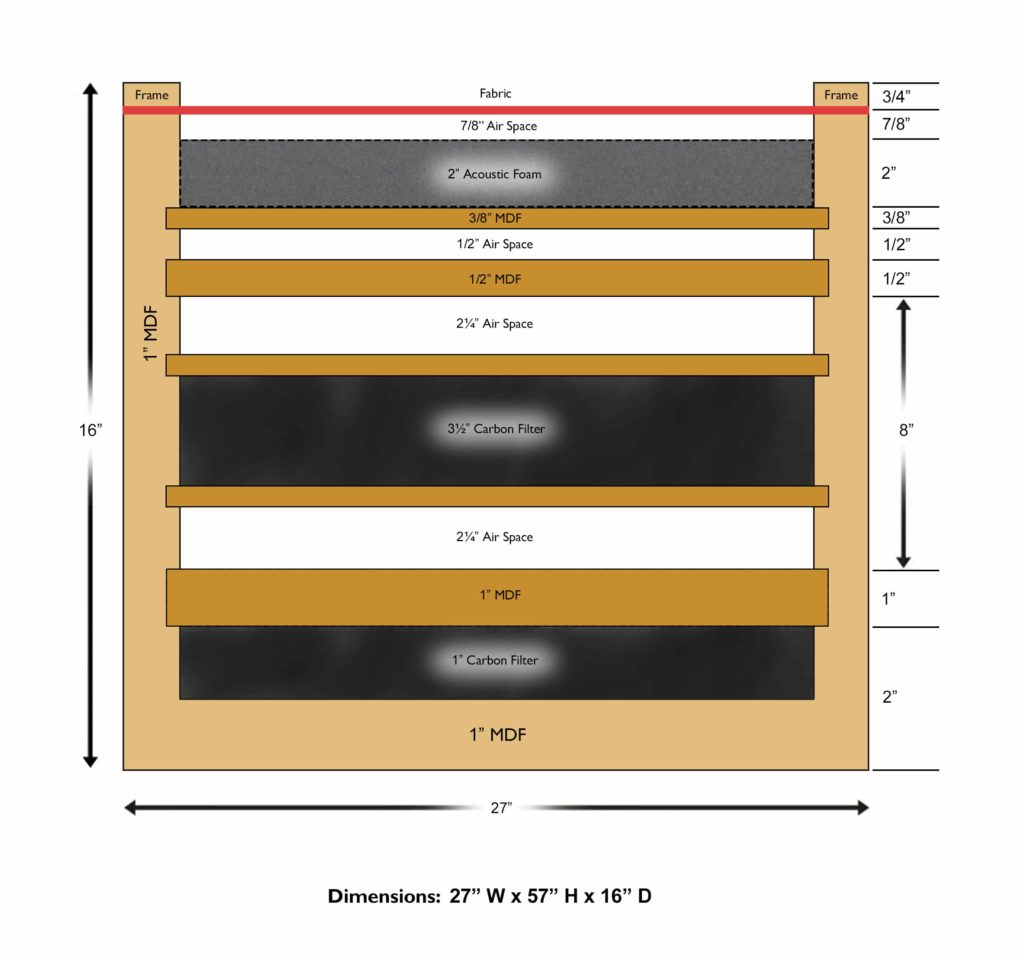

BDA – Broadband Diaphragmatic Absorber DIY

The BDA unit that we are offering is unique in many ways. First, the cabinet design is a tested unit that has undergone vibrational testing in our facility. It is designed to be as inert as possible using only one layer of material. At 4.4 lbs./ sq. ft. it is a heavy unit but the mass is necessary if you are going to attempt to stop low-frequency energy. The front wall has also been calculated to work with the chosen cabinet density and comes in at 2.4 lbs. / sq. ft. Check the DIY Broadband Diaphragmatic Absorber in full here.

Perforated Absorber Cabinet Fill

The internal cabinet fill is not just material inserted into the cabinet. The internal fill material is actually another unit itself. It is called a perforated absorber and is designed to absorb at a frequency that will minimize internal cabinet resonances and then compliment the total cabinet design to achieve absorption down into the 40 cycle range. A perforated absorber is a separate unit that has a front wall that has perforations of a certain diameter and a certain number to produce a unit that has a specific resonant frequency.

Acoustic Fields Foam Panel Technology

FB – Foam Box – DIY

The DIY Acoustic Panels foam box unit is a cabinet that is designed to hold any type of acoustic foam that one desires. There are numerous open celled acoustic foams that are available in the marketplace and our foam box is a unit that one can build that can be finished to match any decor. The fabric face and frame assembly is the same process that we have used in our production units and we have many units that are now over six years old and holding up well. If the fabric is damaged, the face frame can be removed and a new piece put into its place. Check out our DIY Acoustic Panels foam box unit in full here.

QD-11 Quadratic Residue Diffusor – DIY

The QDR-11 is an actual quadratic diffusor based on prime number 11. Each well depth and width has been calculated to produce a diffusion frequency range from 300 Hz.- 3,K Hz. Quadratic diffusion has been time tested and proven throughout the years and is used extensively by professional studio designers. Quadratic diffusers can be used to produce two dimensions of sound diffusion. A vertically positioned quadratic diffusor will diffuse energy in a horizontal dimension. A horizontally positioned diffusor will distribute sound energy in a vertical array.

DIY Diffuser: https://www.acousticfields.com/product/all-in-one-diy-acoustic-treatment-build-plans-package/

Our Quadratic Diffuser with Base

Low, Middle, High Sound Management

We need to have low, middle, and high-frequency sound energy control in our home theater, listening rooms, and professional recording studios. To accomplish this, we need to use sound absorption and sound diffusion technologies. Unfortunately, room acoustic technologies that really work well are expensive and you need numerous units to meet your acoustic objectives. With DIY bass absorbers that you can build yourself, the costs of treating your rooms can be minimized without sacrificing room sonic integrity.

Learn More About Us At Acoustic Fields: https://www.acousticfields.com/about/

In Summary

I hope this explanation helped. Please leave any comments below so I can get back to you. And if you want to learn more about this subject please sign up for our free room acoustic treatment videos and ebook which provide step by step instructions. Get instant access by signing up now.

Thanks

Dennis

Hello Mr. Dennis, I have several questions about room acoustics. I want to ask :

1. How effective Rockwool with 100kg/m^3 density for Bass Absorber Panel?

2. Does leaving air gap between Acoustics Panel with the walls actually gain some benefits?

3. Could I make Bass Absorber Panel using 2 layer of Rockwool 5 cm thick with 5 cm air gap between them?

4. Lastly, how can I improve my subwoofer clarity by using speaker vibration dampener?

Thanks a lot for your inspiring and educative blog post. Thanks in advance for answering some of my question.

J, Building insulation was never designed as an acoustical tool for low-frequency energy.

Thanks for your insight