In a recent Google Hangout, I was asked if there was a performance difference in using a pyramid-shaped acoustic foam vs a wedge shape. There are two things going on here but performance-wise there is no difference. Acoustic foam is a middle and high-frequency sound absorption technology. You can bend it, shape it, twist it, color it, do whatever you want with it but it’s still just a sound absorption technology and not a sound diffusion technology or pressure management technology. We have updated this blog to reflect the current scientific progress on foams. This blog was updated on 11/9/19.

The manufacturer changes the shape for one main reason. It’s to differentiate themselves from other companies because open-celled foam is open-celled foam. You can disguise it, color it, change its shape twist it, bend it, do whatever you want but it’s still just foam. So manufacturers offer different shapes for cosmetic reasons and to differentiate the look of their product from other companies. It is all about marketing hype, hyperbole, and exaggeration.

Performance First – Design Second

When I set out to design our foam technology, I had been testing corporate board rooms for a male voice. I tested over 100 corporate boardrooms. Back in the nineties, males dominated the corporate landscape in Phoenix Az. where I did all my testing. The male vocal range started at 90 Hz. and went through 1,000 Hz. The corporate board rooms had long tables where up to 20 people would sit on each side of the table. What I began to notice was that the last people in line at the table or those sitting farthest from the speaker could not hear and began to tune out or not pay attention. If they were paying attention, they were asking the speaker to speak up. No sound reinforcement was used in these rooms. It was one male speaker with a long wood table and numerous people sitting at the table.

Corporate Board Rooms

Most of the corporate board rooms were long and narrow rectangles. We had 20′ lengths with 10′ widths and usually an 8′ ceiling height. Sidewall reflections were not managed at all and most room surfaces were drywall with pictures on the walls. The pictures were covered with glass. Some of the rooms had glass windows that may or may not be covered. If they were covered, the covering of choice back then was hard plastic vertical blinds or metal mini blinds. Nether the room dimensions or the interior wall structure and coverings were acoustic friendly. Remember with a 90 Hz., low – frequency energy to deal with a male voice we need at least 12′ of space to operate within to avoid resonances.

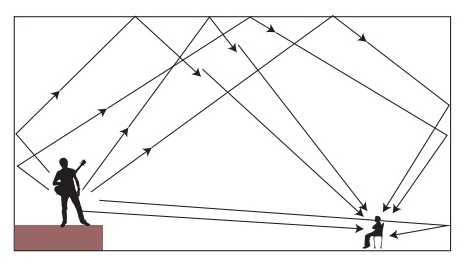

Reverberation of sound in an auditorium

Reverberation : https://en.wikipedia.org/wiki/Reverberation

Speech Intelligibility

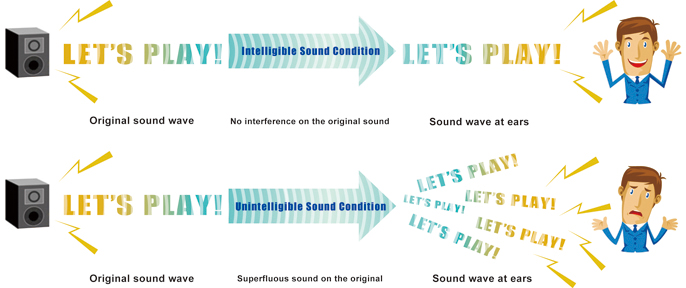

Our goal with any critical listening room when it comes to vocals is speech intelligibility. Speech intelligibility is an index of measurement that tells us how we must manage reverberation times. Reverberation times are the accumulation of all the reflections from the floor, ceiling, and walls. All of these surface areas contribute to reverberation times. Reverberation is room distortion. The reflections interfere with the direct or straight-line energy from the source or in our case a single male speaker. The energy that leaves the male mouth and goes straight into the listener’s ears contains fewer room reflections from the room surfaces. The shortest distance between the male voice and the audience is a straight line from mouth to ears and takes the least amount of time to travel.

Speech Intelligibility Index: https://en.wikipedia.org/wiki/Intelligibility_(communication)

Speech Intelligibility

Design Goals

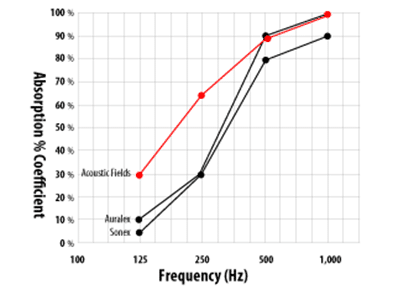

Our goal with any acoustical treatment is to quantify and qualify the problem and then design a solution to treat that specific frequency and amplitudes of the problem. What we noticed with our board room data was that there was a lack of absorption in the 125 Hz. – 250 Hz. region. This is the fundamental of all the other middle range frequencies that produce voice. It is the starting point if you will of everything that we refer to as voice. Most foams we tested in the marketplace absorbed at higher frequencies but did a poor job at the lower registers or octaves for a male voice.

You can see by the chart above that the two current foams at that time in the marketplace fell short in that critical 125 Hz. to 500 Hz. region. This reason is the basis or foundation for voice male or female. You must provide more absorption in this region to absorb middle frequency excess in small rooms. This increased level of performance will go a long way to increase speech intelligibility which is the goal with music or voice. We designed our acoustic foam technologies to increase performance in this critical frequency range. It has made all the difference in the world to engineers who are using our 2″ foam technology.

What Engineer’s Say

Engineers that use our foam in their audio applications tell us two things. First, they say that when they review the recording of voice, they do not grab for delay or reverberation right out the gate. They like the way the vocals sound when they are recorded and do not hear a need to use signal processing. They may add some reverb or delay down the road to make the vocals sit better in the mix but they do not automatically use signal processing in the beginning. What they also say is that our foam technology is “organic” sounding. This means it has a natural tone and texture to it. It sounds like a real voice that you would hear. It is not a voice that sounds like it was recorded in a closet.

Foam Shapes

What you must realize is that foam from a marketing standpoint is boring. It is not an exciting product to market. About the only thing you can do to it is to change the color or shape. You will see many shapes in the marketplace. They are all designed to do one thing and that is to catch the uniformed eye and convince you to purchase the shape and color without looking at the performance. And as we have seen from our discussion of the corporate room data, the foam should be all about acoustic performance. It’s the performance using the foam’s rate and level of absorption that leads us to the proper rates and levels for speech intelligibility.

Acoustic Field’s Foam

Our foam technology is all about performance. It does not come in fancy shapes, or colors. We have one shape and one color. During our research and development phase, we quickly realized that adding color pigment to our acoustic foam decreased performance. Our foam is one shape and one color. If the grey color does not work for your application, it can be placed in a box and covered with fabric. Not any kind of fabric will work. You must have a fabric that allows for the proper rate of airflow to go across the foam. Foam works by having airflow across its surfaces. As the air flows, friction is created that produces heat. This energy change to heat is what produces the absorption process.

Foam Ladder: https://www.acousticfields.com/product/foam-ladder/

Acoustic Foam Panels: https://www.acousticfields.com/product/acoustic-panels/

Hi Dennis, thanks for the great summary of the article. I’m setting up my studio now and find all the different choices a little overwhelming so it is good to have some guidance. Cheers!

Hi David, Lets take a look at your space. Define the absorption and diffusion issues and then match everything to usage. Fill out the information in this link:

https://www.acousticfields.com/free-room-analysis/ This is a free service we offer to compare your room size/volume/usage to our data base of built and measured rooms.

Hi,

Really interesting article.

I’ve just had a prototype water filtration and softening (using filters, not salt) system installed in my house. It needs a pump to push the water through the restrictive filters, which is causing noise, which (seems) especially loud at night, and because it is located near an adjoining wall to my neighbour’s house I’m trying to get that noise to a minimum. So far I have put two layers of dual layer vibration damping mat under the unit, as well as a small amount under the pump feet, which has helped reduce vibration to a minimum, but because it is in a kitchen cupboard, it (I think) is acting like an echo chamber for the low frequency sound. Would lining the cupboard with some type of foam (wedge/ pyramid was my first thought) contain the noise inside the cupboard, and do you have any recommendations, please?

Thank you for taking the time to read this. (I’m in the UK, by the way).

John

All noise must be measured for frequency and amplitude. The barrier design chosen to fix the noise issue is dependent on those two numbers. We can assist you with the measurement and design process.