This blog has been revised since its original posting to reflect new information in regards to subwoofer vibration absorber technology and practices. This blog was updated on 11/17/19.

Sub Woofer Cabinets

Our subwoofers are cabinets that contain a lot of energy for their respective sizes. They also produce a lot of energy for their size. It is like putting a large horsepower engine in a small car. The power to weight ratio is a large number. I used to have a cobra kit car with a 427 cu.in engine that produced 500 horsepower in a 2,300-pound car. That’s about 5 horsepower per pound of car. That is about the same power to weight ratio as a subwoofer. No, I think the subwoofer is a wider ratio.

Same Old Drivers

Subwoofer cabinets have gotten smaller but driver size has not. We still see 12″, 15″, and 18″ diameter drivers in our subwoofer cabinets. Back 10 years ago, if we had a sealed box for a subwoofer and an 18″ driver inside, we had a box that was huge. I remember the Hi-Fi, Velodyne, 18″, subwoofer cabinets that were 40″ long and at least 30″ tall. They had that electronic servo monitor system that provided vibrational energy data to the amplifier when the driver was at its performance limits to avoid driver meltdown and reduce distortion parameters. Cabinet construction was a single layer of material such as 3/4″ plywood or MDF.

Today, Smaller Cabinets

Today, we see large drivers in much smaller cabinets. Technology has allowed subwoofer designers to shrink the cabinet size and still realize low-frequency output in the 20 to 30 cycle range. That smaller cabinet, however, does come with more vibrational issues. If we make the cabinet smaller, we have more pressure inside our cabinet. More pressure means more cabinet vibrational energy that the enclosure must deal with. Smaller is fine if it is stronger.

Past Cabinet Materials

Today’s cabinet materials are different from cabinet construction materials of the past. In the past, to reduce cabinet vibrations, we had to use mass and a process is known as a constrained layer, mass damping. Multiple layers of materials with different densities were sandwiched together. Mass was the key ingredient in the formula. There was no substitute for cubic inches. We were draining the vibrational energy from the noise signature. Multiple layers, different densities, and materials were our tools.

Layers, layers, Layers

Each layer of material was separated from the other by a substance known as a video-elastic damping compound. These multiple layers of materials with the damping compound reduced the amplitude of cabinet born vibrations. The ultimate goal was to reduce cabinet resonances, so they were below the audible sound of the driver in the cabinet. With all of the six subwoofer surface areas vibrating, you now have a speaker inside a speaker. The only thing we want moving is the driver.

New Composites

Today, we have new materials to choose from. We have composites that are made of new polymers that have more strength per square inch than our multiple layer approach of the past. These compounds can be formed into different shapes that are more conducive to speaker internal pressure reduction by having the ability to be splayed or canted to minimize parallel surface resonances inside the cabinet. With the same size drivers as we had in the past, mated with smaller cabinets, something must give and cabinet construction materials have been selected since that is the last surface area of issue. Our goal is a subwoofer vibration absorber in plain speak.

Driver/Cabinet Movement

With a subwoofer, we have cabinet movement even with the new cabinet compounds. A cabinet if moving enough and that movement gets laced with the driver sound, we have now to contend with room sound. The driver moves back and forth to produce a wave of energy. This process produces vibrations that are transmitted through the cabinet. Together, the driver wave output and the cabinet “sound” produce the sound energy that will be sent into our rooms. Subwoofer, sound energy is radiated from all sides, top, and bottom of our cabinet in a 360-degree array.

Room Is Speaker Cabinet

Our room is another cabinet with the same issues that a subwoofer cabinet has. Our room must deal with sound pressure injected into it from our subwoofer. The room then acts its size not its age. Room dimensions determine the room resonances we will have inside our room “cabinet”. The room resonances and the subwoofer produced energy, all work together to produce the final sound we hear in the room. To improve our subwoofer cabinet and driver sound, we need to reduce both vibrational energies from the cabinet and also absorb the low-frequency energy produced by the driver. We want just woofer sound.

Acoustic Fields Absorber Wall Barrier

Diaphragmatic Absorption

To accomplish both of these tasks, we turn to old technology and blend it with a new twist. Diaphragmatic absorption is a time tested and proven method for low-frequency absorption. If it is combined with vibration draining cabinet fill, one can achieve both cabinet vibrational level reductions along with sound pressure absorption inside the cabinet. We minimize physical cabinet vibrations and then absorb excess back pressure within the cabinet created by the diaphragmatic action of the driver or woofer sound.

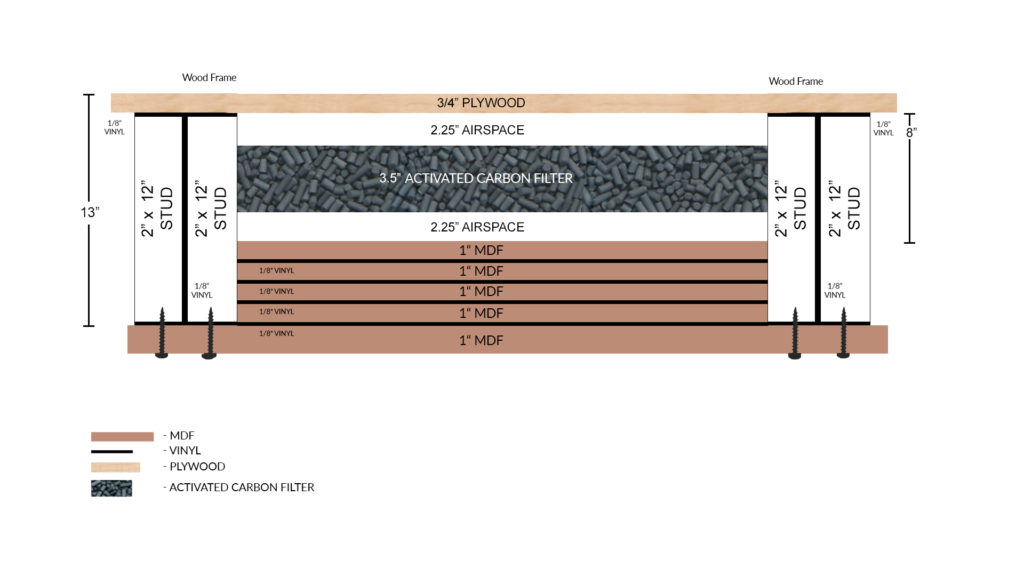

Build Diaphragmatic Absorber

If we calculate the proper cabinet depth and make sure we have the required cabinet material densities in place, we can calculate the approximate cabinet resonant frequency. Frequencies above that frequency will be absorbed and frequencies below the resonant frequency will not. If we add activated carbon or charcoal to our diaphragmatic absorber cabinet, we lower the cabinet’s Q value and achieve both a sound pressure absorber and as a platform for our subwoofer to sit upon. We increase frequency lower levels and all frequency rate of absorption with our carbon technology. Its the same technology as our Carbon Absorbing Wall (CAW).

Carbon Absorber Wall (CAW): https://www.acousticfields.com/carbon-absorber-wall/

Close To The Source

Since our subwoofer cabinet produces energy through all its walls, top, and bottom, we can place our diaphragmatic absorber under the subwoofer and gather a lot of this energy. This procedure works very well if the subwoofer is down-firing. Since our diaphragmatic absorber works on sound pressure, we now have it positioned as close to the sound pressure producing source. Remember our goal is woofer sound only.

Charcoal / Activated Carbon

The activated carbon cabinet fill is also a vibrational reducing material. Activated carbon is a fancy name for charcoal and each piece of carbon or charcoal has numerous pores that assist us in a process to minimize and absorb vibrations. The activated carbon now reduces vibrations and each carbon granule has numerous holes or pores that create a high pore to material ratio thus increasing overall absorption levels and rates with the diaphragmatic absorber.

Subwoofer Absorber Platform

Diaphragmatic Absorption

If we build a diaphragmatic absorber that has the correct material cabinet density, the proper cabinet depth (about 12″) to achieve our targeted overall cabinet resonant frequency and then place the appropriate amount of charcoal within our diaphragmatic absorber cabinet, we have the correct formula for both sound energy absorption and vibrational control. In order to achieve the best results, we must place our subwoofer cabinet on our 12″ high diaphragmatic absorber. Elevating the subwoofer off the floor will also improve our overall room response. One could call it a subwoofer vibration absorber.

Video Camera Carbon Feet Close-Up

Isolate, Elevate, Attenuate

With our carbon-filled subwoofer platform, we isolate, elevate, and attenuate. We isolate the subwoofer from the floor by placing the subwoofer on our carbon platform. The platform provides another layer of different materials between the source of vibration (subwoofer). We elevate the platform 12″, 18″ or 24″ depending on room size, usage, and pressure levels. We attenuate or absorb energy as close to the source as we can get with our carbon technology. The source is sitting upon us. You can not get much closer in proximity than that. A functioning subwoofer vibration absorber.

Acoustic Fields Subwoofer Platform: https://www.acousticfields.com/product/subwoofer-platform-absorber/

Clean And Tight Bass

With all of this in place, we will have a tight, clean, and more dynamic sounding subwoofer. Attack and decay of each bass note is more clearly defined. With an activated carbon absorber close to the speaker, we have an absorber that is pressure reactive right next to the highest pressure source. With the platform elevating the subwoofer off the floor, we improve room response. Our just built absorber is functioning at its maximum ability by elevating to improve room response, absorbing excess energy to improve definition and clarity, reduce vibration and isolating the subwoofer from the floor so they don’t start speaking to each other. We want just woofer sound.

In Summary

Thanks for reading, and as always if you have any more questions or concerns regarding this blog post or others, feel free to get in touch with me at info@acousticfields.com and I will be happy to answer any of your questions.

Thanks and speak soon,

Dennis