Three Sound Absorbing Materials

Most sound absorbing technologies in the market place use three major classes of materials to absorb sound energy with. Acoustic foams have been around for years and most work for absorbing middle and high frequencies. They are light weight and fairly inexpensive. Building insulation is another popular form of sound absorbing material which is also light weight and inexpensive. Fiberglass and rock wool are two common types of this material. Fabrics have also been used to absorb sound energy and a well designed and built drapery system can do wonders for a large glass door or window. These materials are taken by different companies and made into units that can be hung on walls or placed in rooms where absorption is needed and required.

New Kid On The Block

There is another material that we have discovered that works well for middle and high frequency absorption. It is termed activated carbon but we call it charcoal. However, after years of experimenting with different designs and measured performance of these designs, we have found that it works well for middle and high frequency absorption. However, it works even better for low frequency or bass absorption in the correct amounts because of its unique structural properties which allow it to be used to filter water and air. If it can filter water and air, then it can “filter” sound energy, especially low frequency energy, which is found in both air and water.

Activated Carbon Sound Meteors

Activated carbon granules look like miniature meteors. Each granule of charcoal has numerous holes or pores in it. Each pore is a perfect place for sound to enter into and be absorbed. Each activated carbon granule has many pores and these pores translate into a large amount of surface area. If we could unfold one gram of activated charcoal it would equal anywhere from 500 to 1500 m2. One teaspoon of activated charcoal powder (about 3.3 gm.) has about the same surface area as a football field. This tremendous surface area translates into a tremendous potential to “absorb” large amounts of sound energy.

Pore Size Is Critical

The size of the pore in each granule must be designed and manufactured to absorb the medium one wishes to absorb. If you are using activated carbon to absorb certain things found in liquids, you will use one size pore. If you are absorbing elements out of air, you need another sized pore in your activated carbon granules. If you are absorbing sound energy, especially low frequency energy, you need still another.

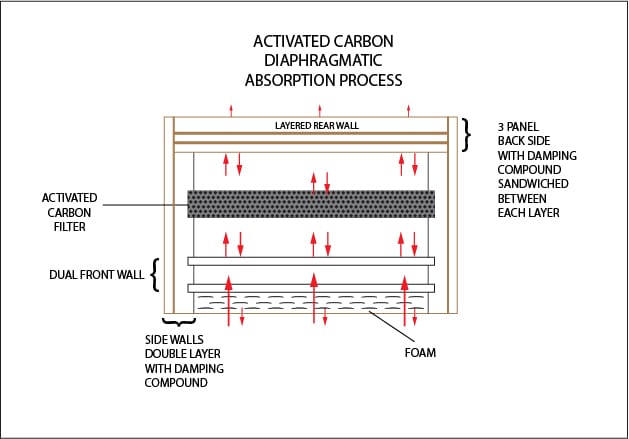

50 Pounds Of Carbon In Each Unit

At Acoustic Fields, we have taken activated carbon and found the correct pore size that will assist us in absorbing low frequency energy within our rooms. We take this calculated pore size and have activated carbon manufactured to our size specifications. After a bath against moisture retention, we then place 50 pounds of it into a specifically designed cabinet that allows the activated carbon to absorb bass energy at a rate and level never before realized in a commercially available unit. The results from our independent lab tests show absorption down into 30 Hz.

Please refer to our ACDA-10 and ACDA-12 section of this site for further information on these powerful, low frequency absorbers. Pay special attention to the Riverbank Labs test results to see how well charcoal works as a bass absorber in a small amount of space.